Started in 2005, Apis Glass focus on manufacturing high quality interior tempered glass, including shower door glass, interior door glass, furniture glass, printed glass mainly use for electrical appliances and furniture as decorative glass panels.

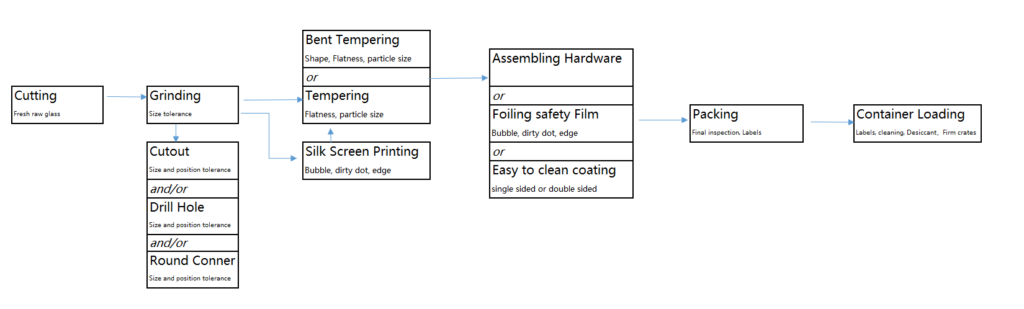

We have a complete interior tempered glass production line, including cutting, edge grinding, drilling, cornering, water-jet cutouts, silk screen printing, flat glass tempering, curved glass tempering, wooden crate packing and express carton packing. Meanwhile, we also provide shower enclosure pre-assembly work and provide additional service like easy clean nano coating, safety film.

We use fresh raw glass sheets within 3 month made by Taiwan Glass, meets international glass standard. Our Automatic Bottero cutting line which imported from Italy can cut 3mm~12mm glass in any shape, including rectangle, round, other irregular shapes.

We always clean up the glass debris on the countertop in time , to protect glass from scratch.

Apis glass grinding machines which imported from Italy produce the impeccable appearance and accurate size edges. We have double edge grinding machines and round glass grinding machines and CNC machines. Can process Polished shinning flat edge, pencil edge(C edge), beveled edge,and matte edge. Our edge works are very much loved for its uniform chamfer edge and smooth hand feeling.

With advanced water-jet cutting machines, automatic drilling holes machines and cornering machines, we could process any cutouts and holes, and corners. The glass shower door panels are going to be installed and used, focusing on this, we process every piece of glass at highest precision within the size tolerance.

After 10 years’ printing practice, we developed a professional team, and rebuilt a dust-free workshop with cleaning air supplied. Use high-temperature environmental friendly ceramic paint from American Ferro and Italian Fenzi, Printed paint before tempering. It has the features of scratch resistance and long time color adhesion. We can print any colors and patterns of your unique design on the glass panel.

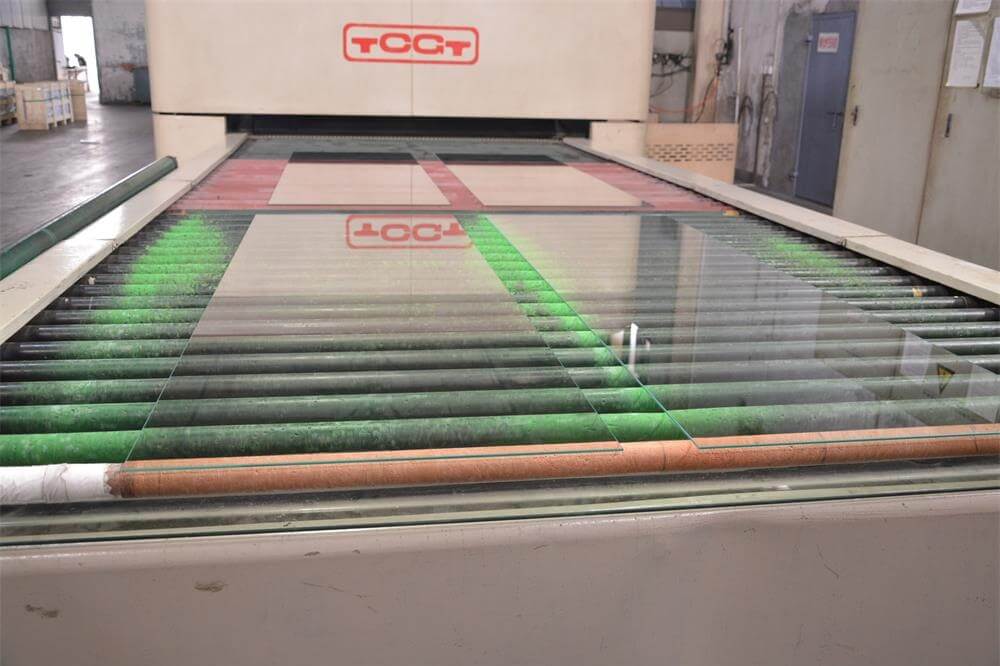

Our company’s internal standards are higher than the European CE and the US SGCC standard basic standards. We inspect the tempered glass on each shift: flatness, tempering particles, and quality inspection report. We comply with a range of tempering particles, which makes the stress of our tempered glass uniform and effectively reduces self-explosion.

16 years manufacturing and exporting shower glass and furniture glass, We’ve learned a lot from the past. Now we know how to pack glass to ensure every piece you receive is perfect and without any damage. Not only ensure safe transportation, but also we make it easy to unload and manage in your warehouse when you received.

Thousands of container loading experience, we know how to pack and reinforce the crates inside the containers so every piece of your glass arrive you safe and perfectly.

Due to our customer’s requirement, we have owned ability of Shower Door Assembling and Sales-Package Packing. After 15 years practice, we have developed a professional team of shower enclosures. We have rich experience and knowledge for assembling and resource of components like Aluminum Profile, Marble Tray, Brass Hinge, Hardware and Spare Parts.

We have an experienced and professional sales team to serve you and fully understand your needs. With our 20 years of valuable experience in interior tempered glass, we can better help you and your brand.