Are you trying to create the best brand for tempered glass products? Many glass buyers are confused to find a well-matched temper glass suppler while starting the top of the glass business. Then, this guide is the right place to help you.

There are many types of tempered glass like tempered window & mirror, shower glass, radiator glass or tempered glass table top. You must know how to ensure there is high glass processing quality in glass factory before you receive those tempered glass panels.

In a tempered glass factory, quality management is, of course, focused on the construction of the system (ISO9001). Besides this quality control system on toughened glass, it is also necessary to carry out continuous management work according to the characteristics of its own industry and factory.

Moreover, quality management should be holistic, covering every single aspect of the glass manufacturing process from the procurement of high-quality glass raw materials to the packaging and shipment of high-quality tempered glass sheets to be delivered to the buyer.

Glass Express Shipping from factory

Therefore, here we summarize the quality management of tempered glass processing factory in three main sections: raw float glass quality, tempered glass process quality, packing & delivering Quality.

Here are the descriptions of each section and the factors you should consider to ensure the tempered glass quality in factory.

Ensure the raw float glass quality

Obviously, no product will achieve high quality if the raw materials used to manufacture it are not high-quality raw materials.

Therefore, it is essential that you can verify that your glass plant acquires good quality raw float glass to manufacture custom high-quality tempered glass products for your business. But how can you verify the quality of raw float glass? Here are some ideas from APIS Glass.

How to buy good quality raw float glass in China?

The first step is verifying the raw float glass supplier selection. Not only the float glass supplier should be reputable and experienced, but there are also other aspects to consider. Key points to verify the float glass supplier include, but are not limited to:

- Customer evaluation.

- The fuel used by the float glass

- Safety and environmental regulations compliance.

There are dozens of raw float glass companies in China, some of which are highly reputable in the market and have stable quality. Popular brands are:

- Taiwan Glass

- Jinjing

- Xinyi

- CSG

Yet, the same float glass company may have different production plants, and even production lines could be different within the same production plant. Examples of these differences include:

- Having new and old production lines working one next to the other

- Using different fuels such as natural gas, coal-to-gas, oil, or even coal.

Generally, the quality of natural gas and coal-to-gas is better, followed by oil and coal, but both oil and coal pose environmental risks which you may want to avoid at all.

Glass selection of float glass

Perhaps the most obvious aspect is the float glass selection per se. Here, there are two key points to keep in mind which are the grade of the raw float glass and the amount of iron contained in the float glass.

First of all, while each float glass company has its own grading method for the raw glass, the grades can be roughly divided into 4 categories like this:

- Mirror-making grade.

- Automotive grade.

- Architectural grade.

- Non-standard.

In APIS glass factory, we have always preferred automotive-grade from float glass supplier. The reason is that, according to our 16 years of tempered glass processing and production experience, indoor glass like glass panels for showers, tempered glass bathroom, or outdoor table top glass, can achieve sufficient quality with automotive-grade glass while maintaining a very affordable and competitive price.

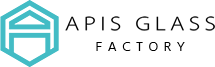

Speaking of the iron content in raw float glass, there are some key indicators to consider. The first characteristic you can easily verify is that the maximum iron content for clear glass is 0.13%. But how can you verify it?

First, if the iron content is high, the color of the glass product will be turquoise, and the transparency (light transmittance) will be low.

So, if you notice the color to be rather intense, and there is limited transparency, you may need to ask for the iron content test report of raw float glass. It is necessary to select a tempered glass factory or raw float glass factory with an iron content test report. The iron content test report will allow you to learn about the percentage of iron in the glass the factory is offering.

Now, if you ask for it, and the glass factory does not have it, you can discard that supplier immediately.

Iron content test in glass

Purchase inspection of raw float glass

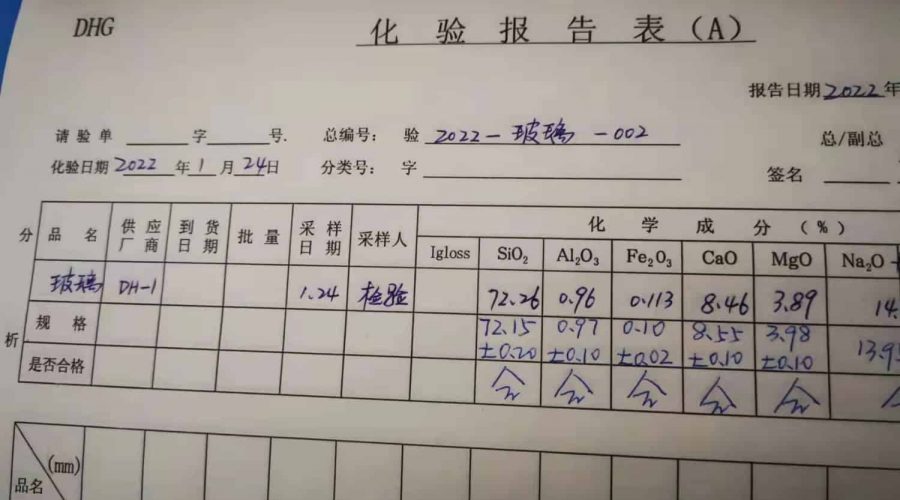

After you have moved through the previous points, and the raw float glass factory is convincing you so far, you still need to inspect the float glass which has been delivered to glass processing factory. At this point you want to learn more about the main properties of the raw float glass such as sizes, thickness, production date, etc.

1) Raw float glass tolerance

Your basic requirements regarding tolerance for clear float glass should cover the following:

- ±0.20 mm tolerance for glass within the standard thickness 2 – 6 mm.

- ±0.30 mm tolerance for glass within the standard thickness 8 – 12 mm.

2) Production date of Raw float glass

In addition, the glass production date is essential to guarantee the freshness of the glass you purchase. The fresher the glass, the better the quality of it and the quality of the final tempered or non-tempered glass products. This way you can step further to get the best quality tempered glass.

The freshness of the float glass becomes especially important during the wet season. This season requires you to carefully store the glass whose production date is more than 6 months, and strictly check whether it is moldy.

Even if you believe the raw float glass is fresh enough, it is always better to check before putting it into production. Here are the steps to take to ensure the raw float glass is suitable for production:

- Cut a piece of the raw float glass you want to inspect.

- Clean it carefully.

- Observe it under the light for mold and mildew, or any other pollutants.

Observe the glass quality after cleanin

Check the production date of the raw glass

lass that requires a printing process (ceramic tempered glass or silk screen glass) also requires special inspection of raw glass tin points. When producing raw float glass, the glass is put to float on a bath of molten tin, hence the name.

The side of the glass that is in contact with the bath will get traces of tin or tin oxide deposited on the surface, making that surface smoother.

When it comes to glass printing, it is important to identify the tin side of the glass to avoid undesired reactions with the ceramic ink components, thus achieving a better printing result and a higher quality printed tempered glass product.

How to ensure tempered glass processing quality in factory?

Ensuring the tempered glass is properly processed in factory is more important than many people think. If you want to ensure tempered glass processing in factory is done properly, you need to verify the following tips:

The right glass processing equipment is in place

If funds allow, choose better glass processing equipment as much as possible. For example, Apis’s equipment comes from Italy, or China’s top glass equipment manufacturers.

The best tools are used in glass production

Good tools always help you do more with less. While the tools we have chosen for workers may be a bit more expensive, we believe that ensuring consistent tempered glass quality and productivity is paramount.

Stable workers committed for the long-term objectives

We always try to retain our employees, that is, retain the experience and technology. More than 14% of our employees have worked with us for more than ten years in tempered glass manufacturing.

Clear glass processing instructions

Instructions must be extracted from each process of glass production and updated every year to ensure tempered glass production standardization.

Organize the general technology and worker training

Organize the general technology every year and conduct unified worker training to reduce tempered glass cost. We do it in different ways, and we want to share some examples with you.

- When loading and unloading glass on the production line, the glass cannot be dragged to avoid being scratched.

- The tempered glass must be secured on the turnover rack before it can be transported to avoid falling.

- The tape measure is measured along the edge of the glass sheet to avoid measurement errors caused by skew.

Glass bundled while waiting to be moved

Glass bundled while waiting to be moved

A concise and clear work list before and after work is provided.

This can ensure the consistency of toughened glass and normal glass production and documents, ensure that the equipment is maintained, and of course, the workers’ occupational safety equipment is worn to avoid injury.

Glass processing equipment maintenance is done as planned

We insist that the equipment should be overhauled every 4 weeks, and the equipment operating with water should be overhauled every 2 weeks. This practice significantly reduces the glass production interruption caused by equipment downtime, which can also affect the delivery time from tempered glass supplier.

How to pack and transport tempering glass safety?

A part of ensuring the tempered glass quality in factory that is often overlooked is the packing and shipment stage. If you really want to ensure the tempered glass quality in factory, this is something you cannot take for granted.

Here are some ideas from our knowledge and experience.

Tempered glass packed in wooden cases to guarantee the glass integrity.

1、Choose a stable and long-term wooden board supplier to ensure the quality of the board.

2、The wooden box should have a reasonable structure, the corners should be crossed, the side must be full, the forklift hole recommended is 100mm, and the box should be sealed with screws for easy opening by the tempered glass buyer.

Wooden box making for APIS toughened glass

Screw-sealed wooden box for glass

4、Wooden boxes can be stacked in three layers, provided that they are tied together.

Glass trapped to prevent from falling off

3 layers of wooden boxes stacked

Loading reinforcement to ensure no accident while tempering glass transit

Steps we take to achieve this reinforcement include:

-

- The upper and lower wooden boxes are connected by wooden boards to form a whole.

- Each row is reinforced left and right to avoid lateral movement.

- Reinforcement at the end to avoid back and forth movement.

- Packages and crates are fixed inside the containers with thousands of container loading experience.

- Both wood blocks and steel belts are used for reinforcement.

stableloadingfor shower glass in container

Two wooden boxes link reinforcement in container

Advanced Tempered Glass from APIS Glass

We want to remind you that buying high quality toughened glass for shower glass, radiator glass or table top glass is a professional selection. It really comes down to getting the best raw float glass and applying the best practices for glass processing and integrating them in every stage. Do not take anything for granted.

Follow our suggestions in this guide and you will have good results. We speak from our own tempered glass manufacturing experience. It has worked for us year after year with brands to build custom temper glass sheets.

Yet, if you still find it difficult to ensure the tempered glass quality in factory, we recommend you find a temper glass supplier that meets all your requirements to produce high-quality tempered glass.

With our 16 years of experience we can provide, adequate workspaces, skilled and trained personnel for each of your custom glass products, the reliable quality and durability in each of the glass sheet, being an environmentally friendly factory and having an optimal workspace for continuous glass production to meet your needs.

Apis glass has an experienced and professional team that is ready to provide solutions for different tempered glass or normal glass products. Contact us now! We will be more than happy to serve you.